Industrial label printers are mainly found in offices, production and shipping.

The thermal transfer printing technique is based on the use of a print head and a thermal transfer ribbon or thermo-sensitive labels. The print head has a line of heating points that are individually activated by the software. Either the heat transfer from the head to the ribbon allows the colour or black pigments of the ribbon to be transferred to the printing medium or, in a so-called thermo direct process, i. e. without the use of ribbon, the label is coloured under the influence of heat in the activated area.

But before you can benefit from the freedom to develop your label layout, you will need to choose your partners for the purchase of software, printer and consumables (print heads, pressure rollers, thermal transfer ribbons, labels, head cleaning products…).

Which industrial printer to choose?

The following criteria play a role in the choice of printer purchase:

Width of labels to be printed.

Desired printing result (darkness and font accuracy = resolution (*)).

The printing speed.

Principle of operation of the print head (Flat Head, Near Edge, True Edge) (**).

Application area environment (dust generation, application area temperature (< 4° C ?), robustness).

Print volume (how many labels are printed per day – 1000, up to 3000 or more?).

Interfaces required.

Desired peripheral equipment (cutting, perforation, stacking, winding and unwinding,…).

Should I print in several colours (e. g. red/black), with symbols or only text / barcode?

Which process to choose: direct thermal transfer or thermal transfer? (***)

Price of the printer and its main wearing parts.

Options such as optimization of ribbon consumption

Availability of the main wear parts and alternative sources

Our advice: do not let yourself be bound for many years by maintenance contracts – with us, you pay a fair price for the main wearing parts: print heads / thermal bars, rollers and ribbons! These are components that are easy to replace.

Manufacturers want to close the door with contracts against good resellers and bind their customers. This is a way of demotivating the user to focus on the price of the often most ornamental wear component, the print head, when its replacement is easy.

If you buy a suitable printer, adapted to the environment and printing volume, the device will remain robust even after the warranty expires.

The advantages of thermal ribbons are:

Flexibility of installation

Choice according to the required printing speeds

Multi-support (vellum, coated, PP, PE…)

High definition depending on the resolution of the head

Economical because

You determine the price/quality ratio. Quality also means resistance to the environment over time: resistance to friction, humidity, solvent, heat, ozone…

Width cutting according to width requirements to optimize use and reduce waste.

Which thermal tape to choose?

In order to obtain the desired printing image in both darkness and hold, different parameters interact:

The printer

Type of print head (flat head, Near Edge or True Edge (**))

Adjustment parameters

printing speed

contrast / temperature adjustment

Thermal transfer ribbon (wax / wax-resin / resin)

The medium to be printed (label, film): are they labels made of matt, glossy, PP or PE paper?

The printing environment (temperature / humidity of the printer environment)

It is necessary to find the best compromise for the desired printing result. If there are different labels with different structures, ask yourself whether it makes more sense to manage a stock of different suitable ink ribbons or find a quality compromise with which each label can be printed.

In short, the more closed the surface of the substrate, the more resin must be present in the composition of the tape to ensure the durability of the printed substrate (friction and scratch resistance).

In the case of open-pored paper labels, choose rolls of thermal wax ribbons, as heated ink particles can penetrate the paper structure.

With Near Edge technology, the residence time of the ribbon for printing is shorter than with flat-head print heads or otherwise the color particles must be released much faster from their polyester backing when passing along the heating line of the thermal strip. Thus, the components that form the ink to be deposited, the formulation of the wax/resin….. are adapted.

(*) Resolution

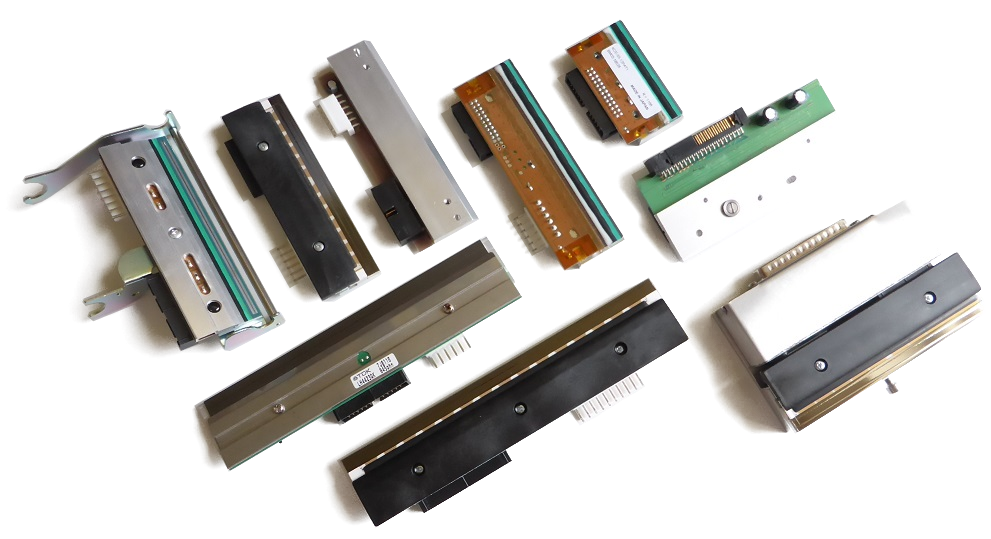

The print head (also called thermal strip) has a heating line made up of different points aligned according to a variable density.

8 – 203 dpi (dot per inch = dots per inch): 8 dots per mm, corresponding to 203 dots per inch.

(common choice, especially for shipping labels),

12 – 305 dpi: 12 points per mm, or 305 points per inch

(also common, depending on the images and fonts used),

Fewer are the resolutions of 16 – 400 dpi and 24 – 600 dpi – e. g. for small electronic labels with symbols. To be considered only for small labels. Less current, therefore more expensive – in principle the human eye no longer differentiates between resolutions above 300 dpi.

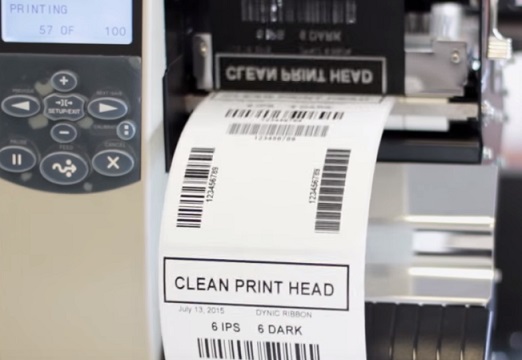

Knowledge bonus: The print head is in permanent contact either directly with the thermosensitive label (if working in thermo-direct mode, i. e. without thermal ribbons) or with the thermal ribbon during printing.

By choosing a higher resolution, the image of the printed media (film, label) becomes thinner or more readable, but the maximum printing speed decreases.

(**) Flat-head or Near-edge thermal head?

There are two main types of label printers on the market:

The “Flat Head” and “Near Edge” versions.

Flat Head

First technology on the market for barcode printing.

Still the most used print heads with print resolutions from 203 to 600 dpi. When printing and thus passing the pair of thermal ribbons / label under the heating line, there is contact between the ribbon and the label over a distance of 3 to 5 mm. This allows the heat emitted by the print head to be easily dissipated and the ink to adhere to the label. Print speeds of up to 300 mm per second are possible.

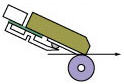

Near Edge Head

In this case, the heating line is on the edge and the printing contact is made at an angle of ± 45° (corner edge) or 90° (true edge). There is only 203 or 300 dpi resolution available.

Corner edge and True edge

As the heat transfer takes place on the edge, the contact surface of the print head, ribbon and label is very small (0.1 – 0.3 mm). The thermal transfer ribbon is thus guided upwards at an acute angle and without additional deflection.

The maximum printing speed is approximately 600 mm/s.

Therefore, the structure of the thermal transfer ribbon, i.e. the formulation of the ink layer applied to the PET film, is adapted to these conditions. The ink layer (< 1 g/m²) of the Corner Edge print heads is thinner than the ribbons designed for Flathead (± 4 g/m²). Less ink is applied and therefore less ink is applied by scraping with the nail on top.

True edge is used when printing cards.

Good to know: With both types of print heads (flat head or near edge), you can reduce the consumption of transfer ribbon at some manufacturers. To do this, you need a transfer ribbon optimization unit in the printer (this can be an option). The print head lifts when printing is not in progress. With the Near-edge print head, the economy of the transfer ribbon is better, i.e. the optimization works better than in flat head.

(***) Print in thermodirect mode or by interposing thermal ribbon?

Which of the printing processes to choose ultimately depends on the intended use of the labels.

In the direct thermal transfer process, heat is transferred directly to the label to create a printed image. Labels have a heat-sensitive white top layer and a colored layer under the surface, usually black, that appears as soon as the label passes under the heating points of a print head.

If the readability of the label is limited to a short period of time (e. g. in the food industry) without high demands on the durability of the print, the Thermo Eco quality is sufficient for the labels – e. g. for printing shipping labels or marking food. For higher requirements, there is the Thermo-Top quality, which requires more heat from the print head.

In the thermal transfer process, the heat generated by the print head is transferred to the so-called thermal transfer ribbon between the print head and the label, causing the ink to separate and transfer to the label. The choice of the appropriate film (expected price/printing result ratio) ensures excellent durability and resistance to abrasion and solvents. Labels that are exposed to the weather later on remain legible.

Wear and tear on the print heads in the direct thermal process is greater than in the use of thermal transfer films, which are provided with a back coating (smooth polyester) that protects the print head against excessive abrasion. As the surface of the label is rougher, the manufacturers of the print heads do not give a guarantee of km of thermodirect printing.

A good consultation with the label supplier and careful maintenance (regular cleaning) of the print heads will help you here.